Morristown West

Student & Faculty awards

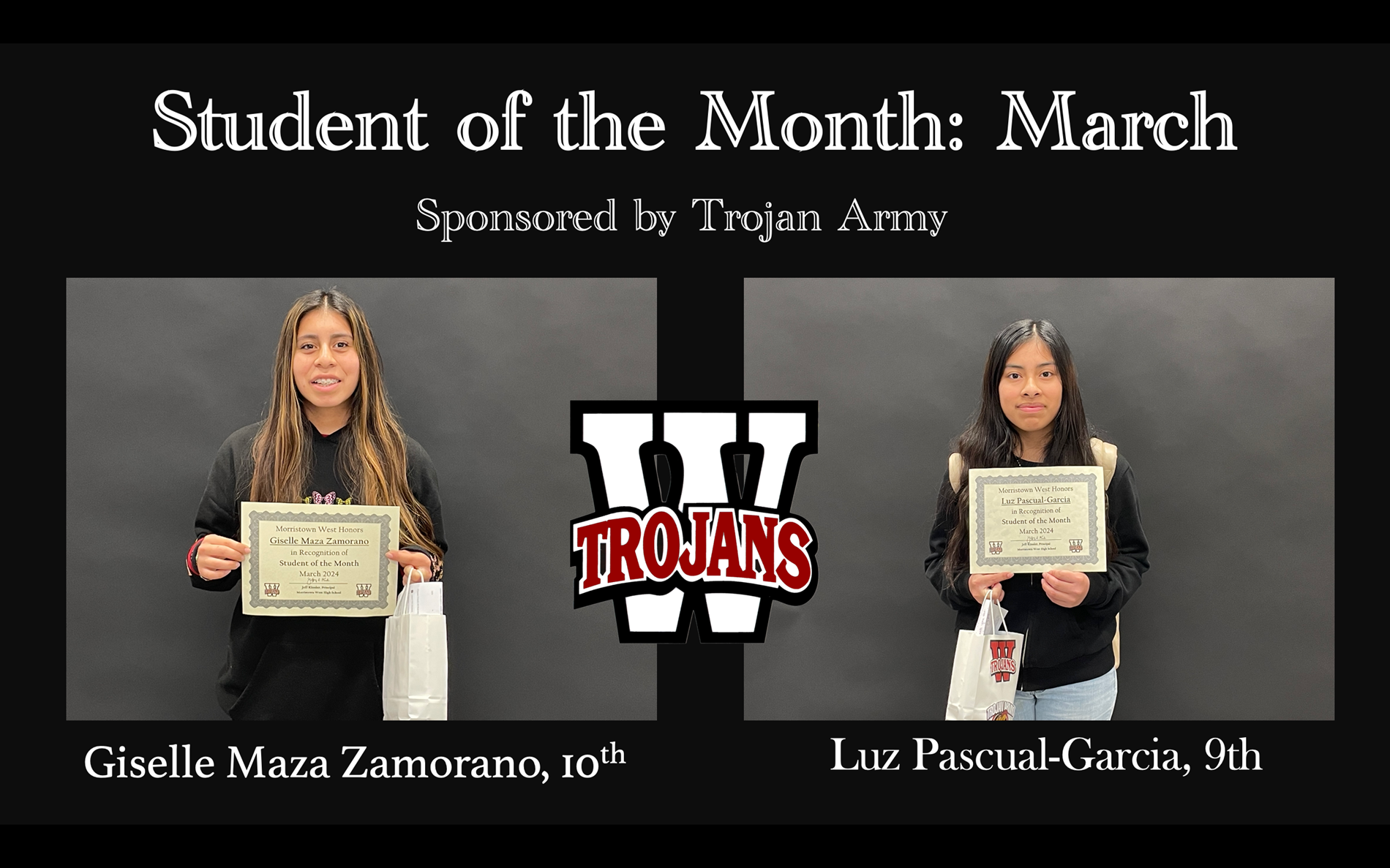

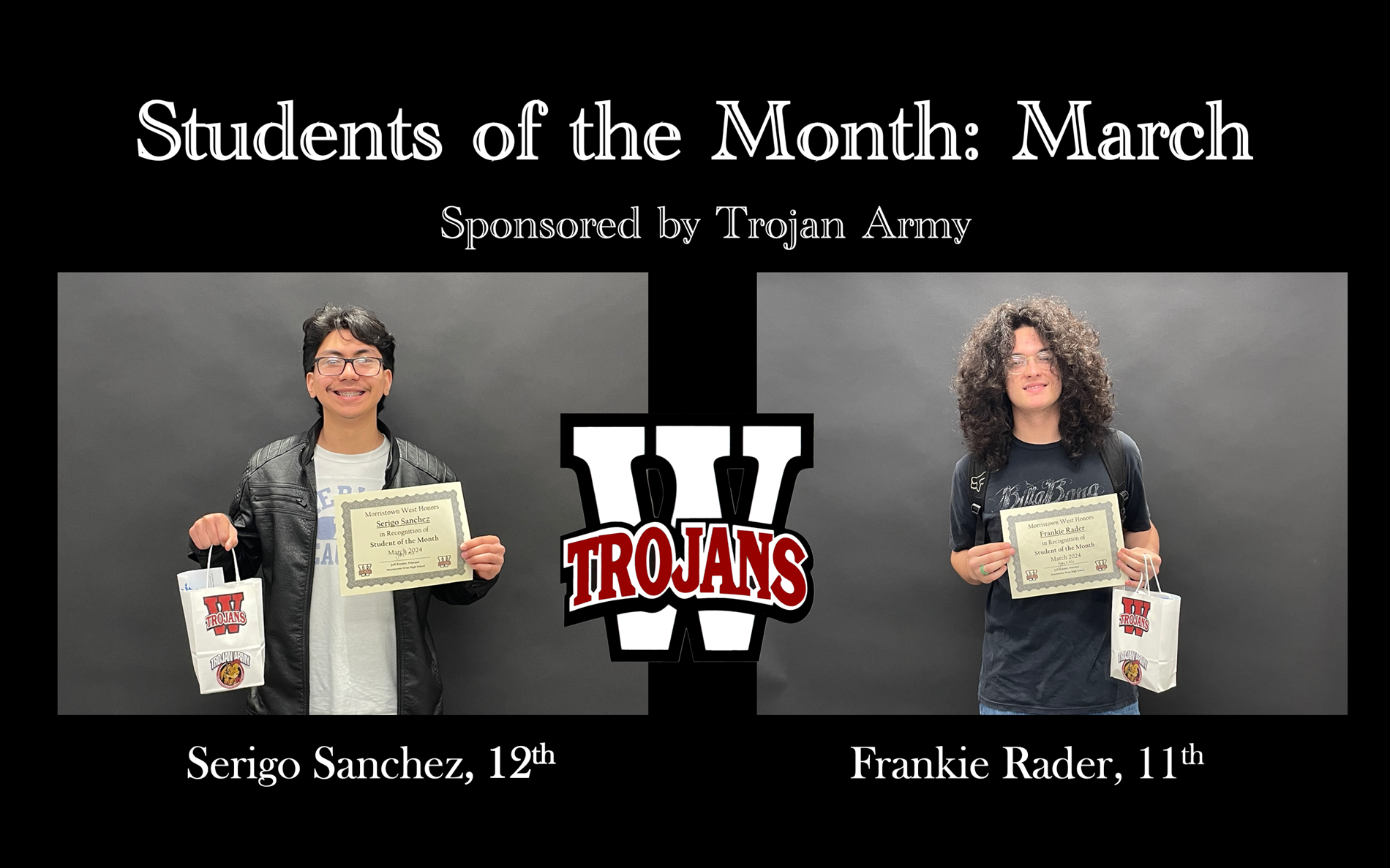

March 2024 Students of the Month

Sponsored by the Trojan Army

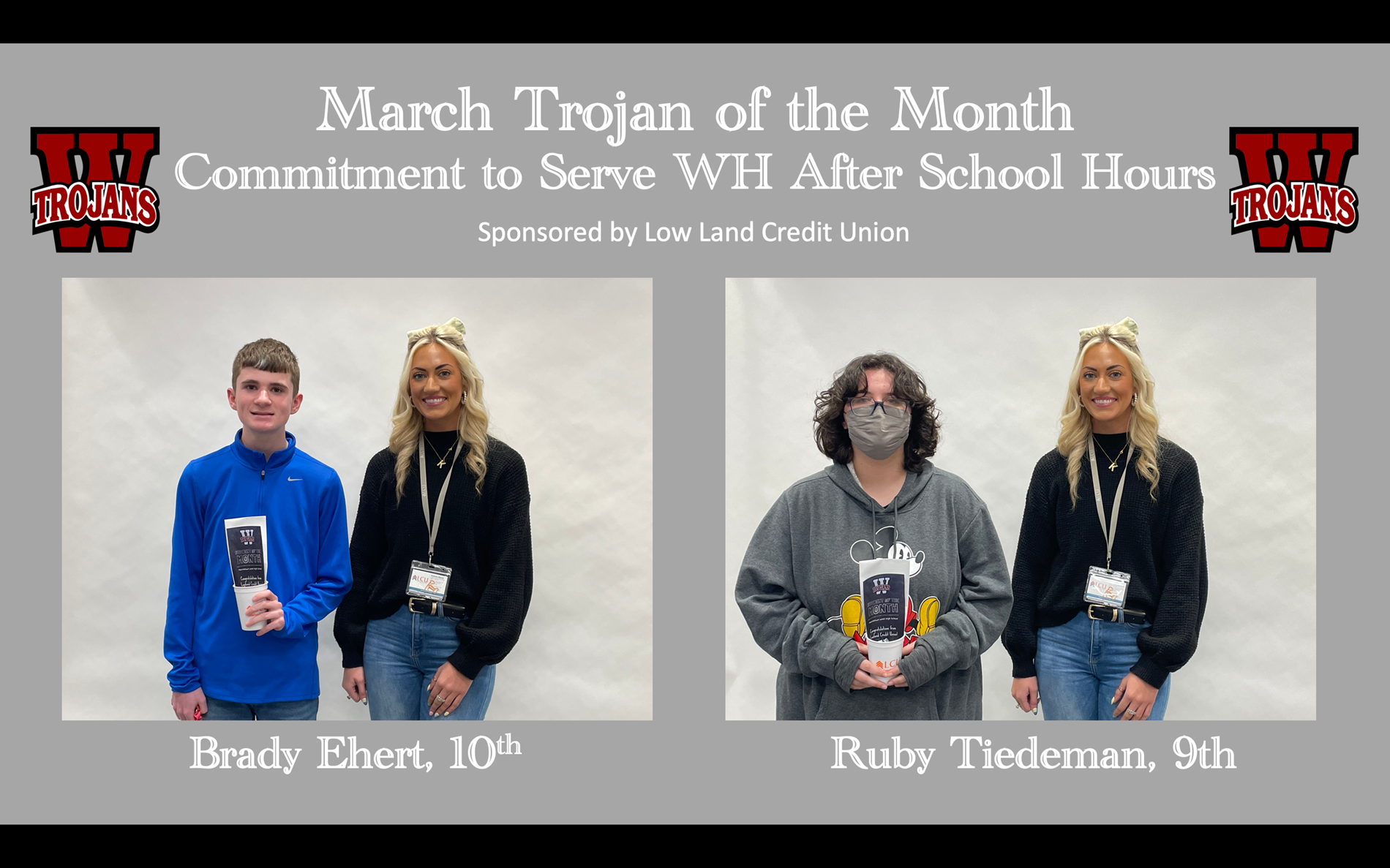

Sponsored by Lowland Credit Union

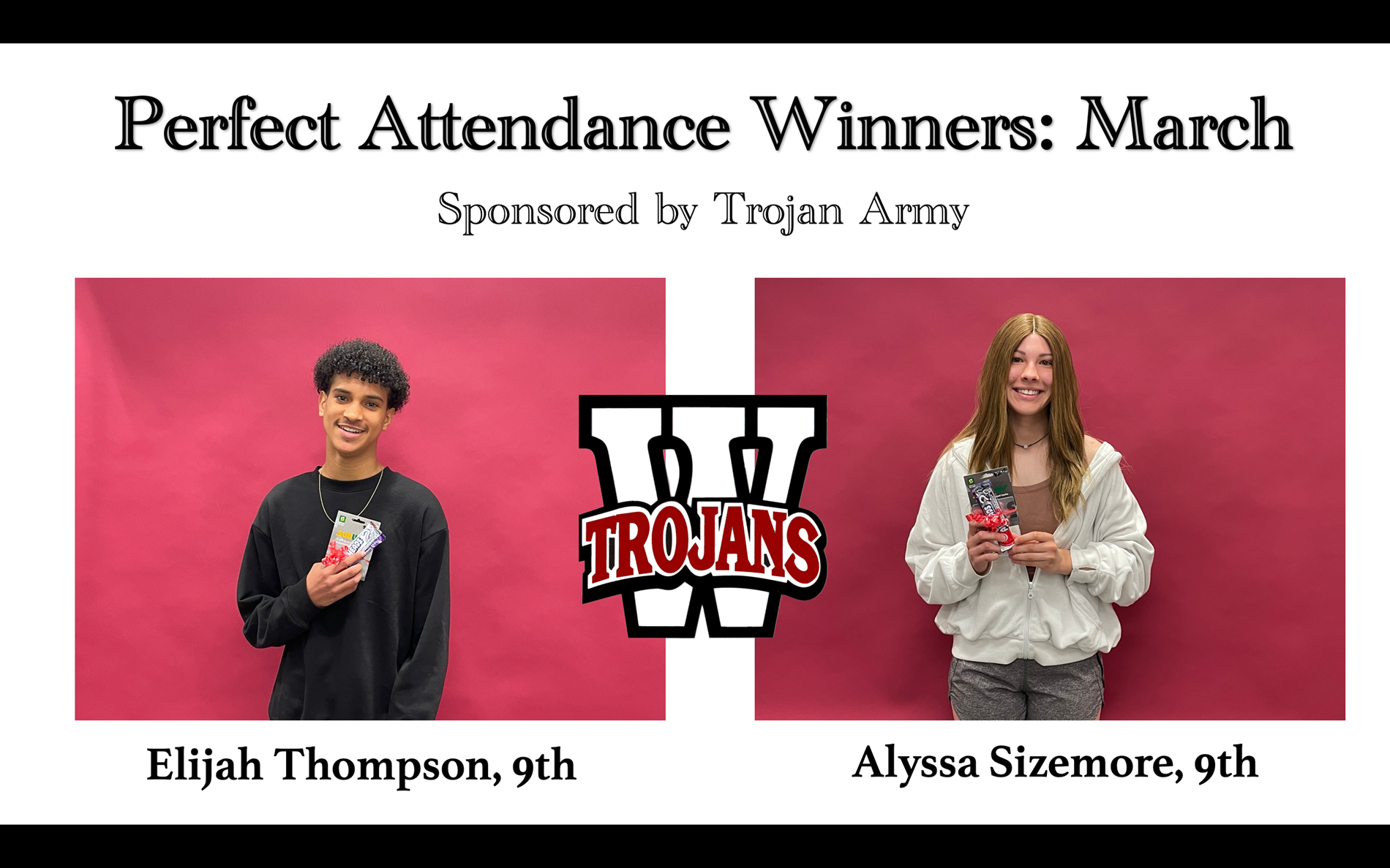

March perfect attendance

Congratulations Ms. Tara Phillips!

Hamblen County District High School Teacher of the Year